Categories

DOWNLOAD

Contact Us

- Hangzhou Skot Imp. & Exp. Co., Ltd.

- Contact: Mr. Seven KOT

- Mob/WhatsApp: +86-15868137919

- E-mail: sevenkot@outlook.com

- Skype / Wechat / Line: sevengeil

- Add: Zhuantang Town, Xihu District, Hangzhou City, Zhejiang, China

- Working hour: Monday - Saturday (9am - 6pm)

Categories

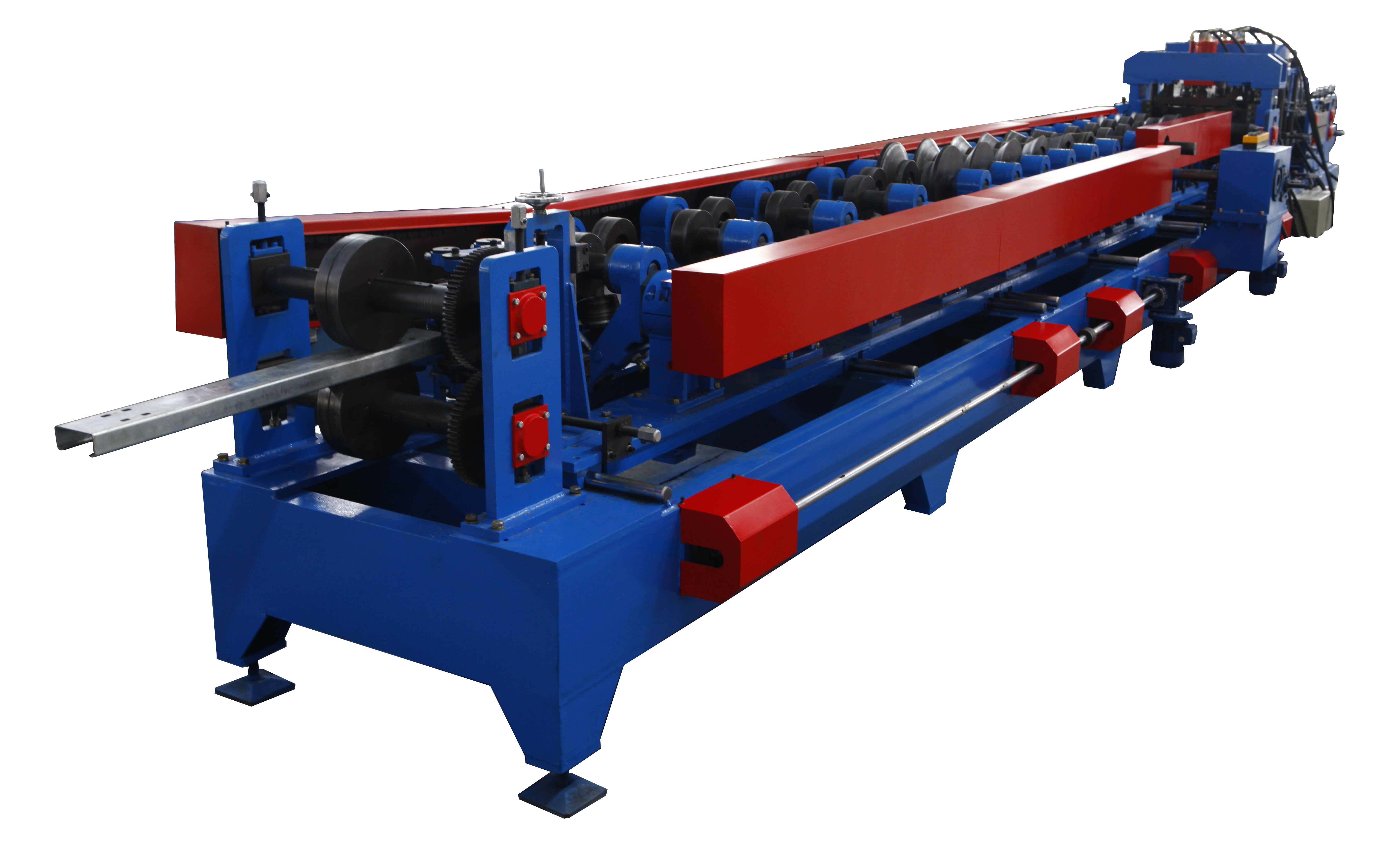

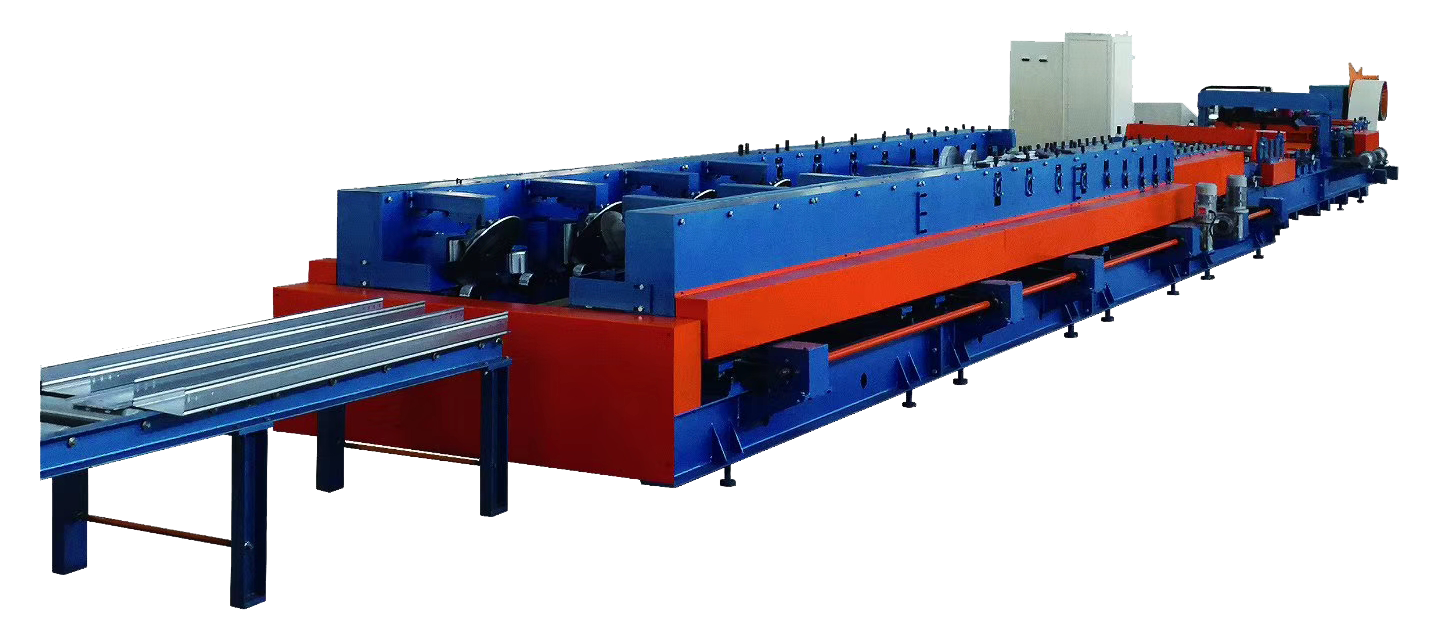

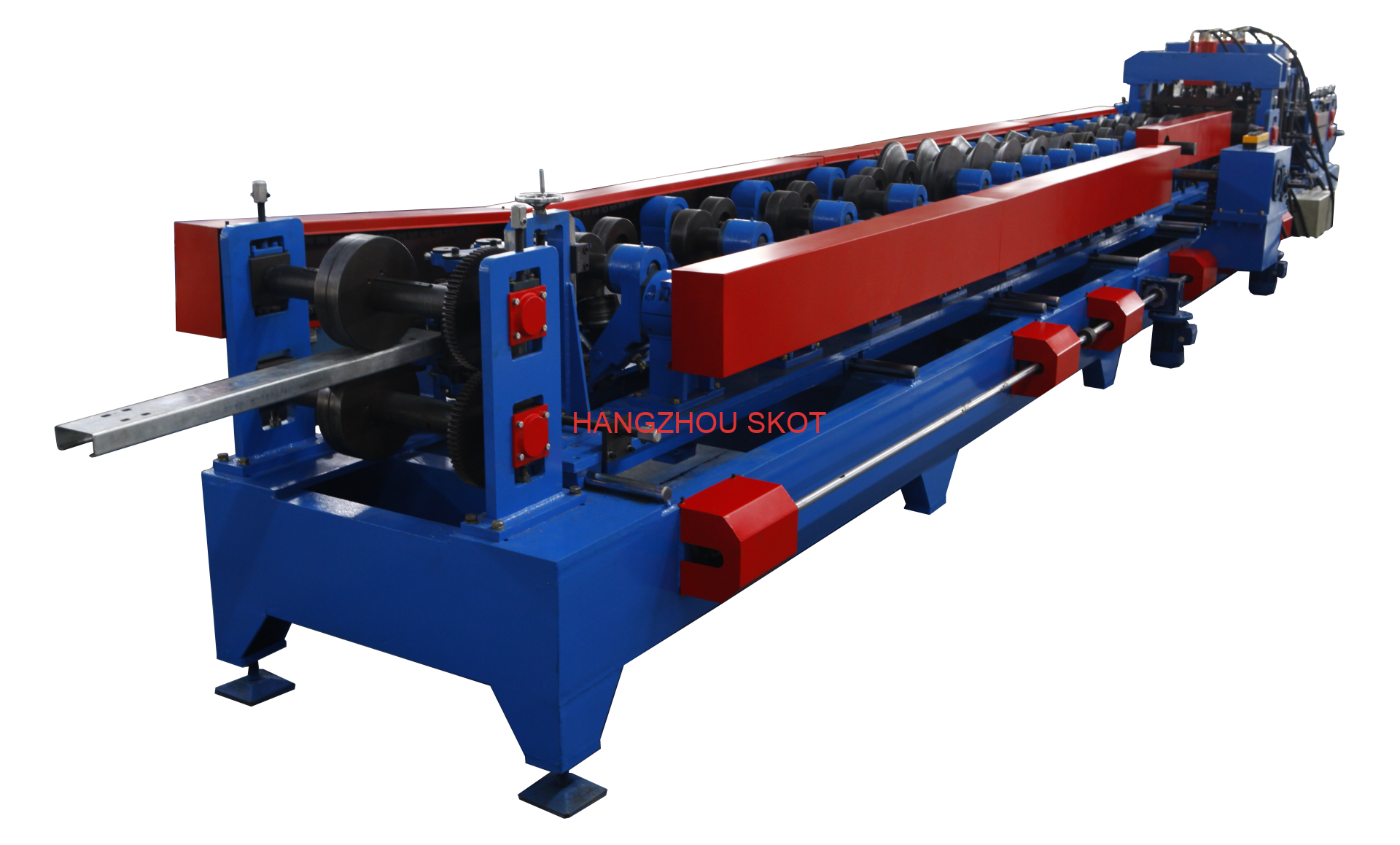

STEEL PURLIN ROLL FORMER

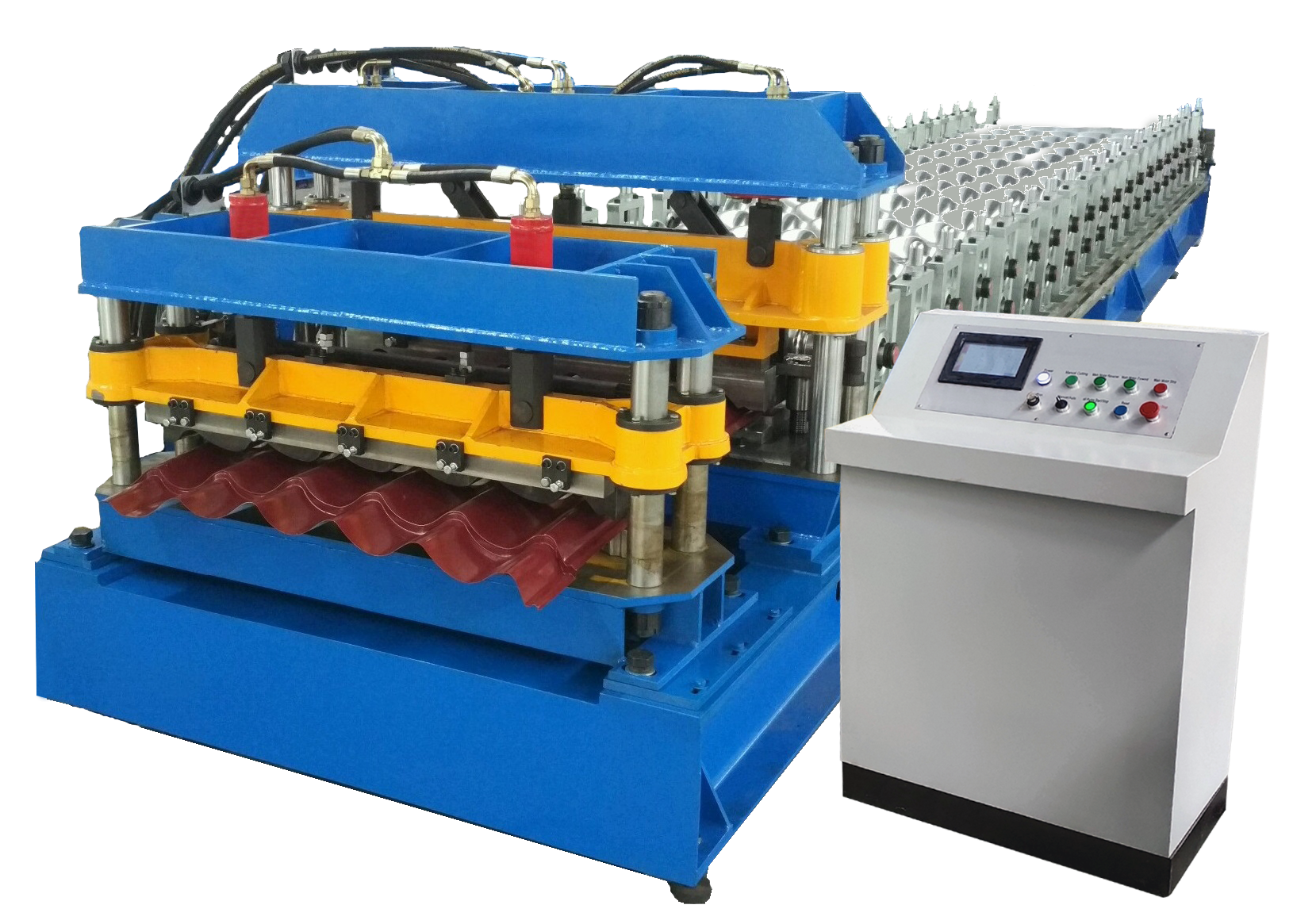

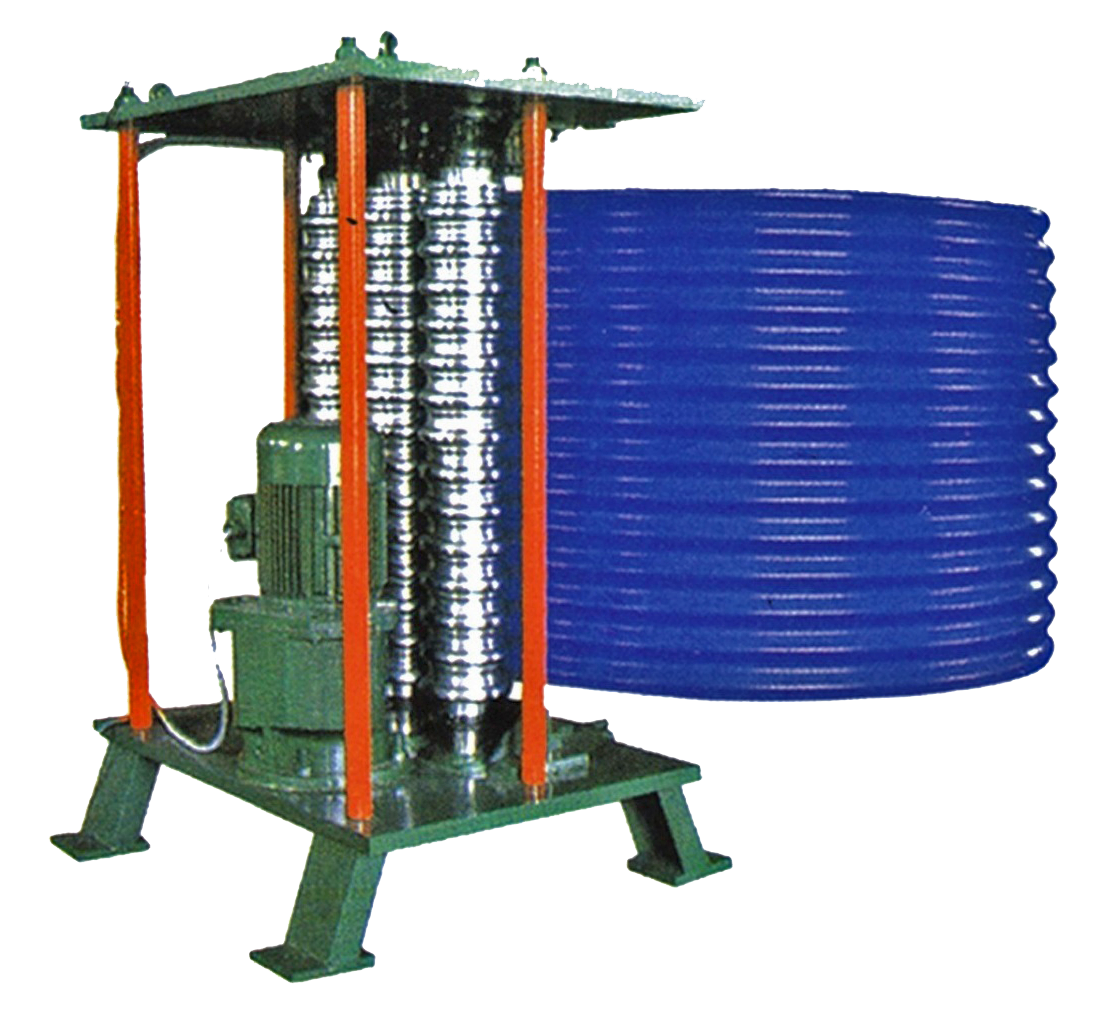

Our equipment is manufactured based on top technology and experiences, and the Roof Panel Producing Line has high durability and convenient management. It enables to manufacture the products of world’s best grade designing various wave forms exquisitely to meet customers’ requirement. The trapezoidal and corrugated metal sheets prove the high quality degree reached by the roll forming systems according to the international standard. Here, you can analyze the data profile of the main products manufactured by our machinery.

Our equipment is manufactured based on top technology and experiences, and the roll forming line has high durability and convenient management. It enables to manufacture the products of world’s best grade designing various wave forms exquisitely to meet customers’ requirement.

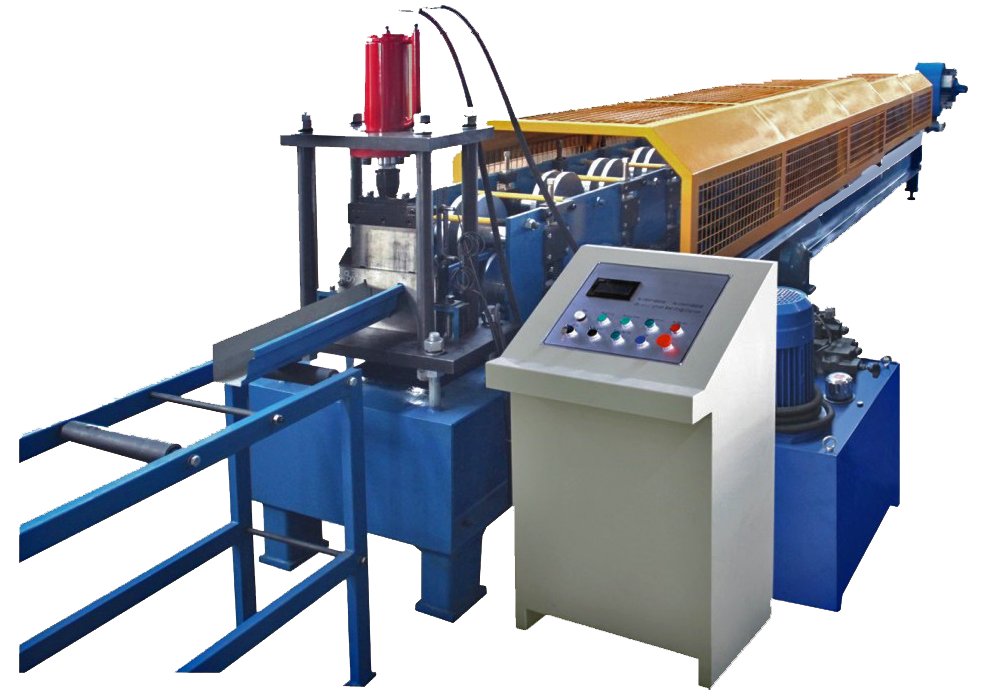

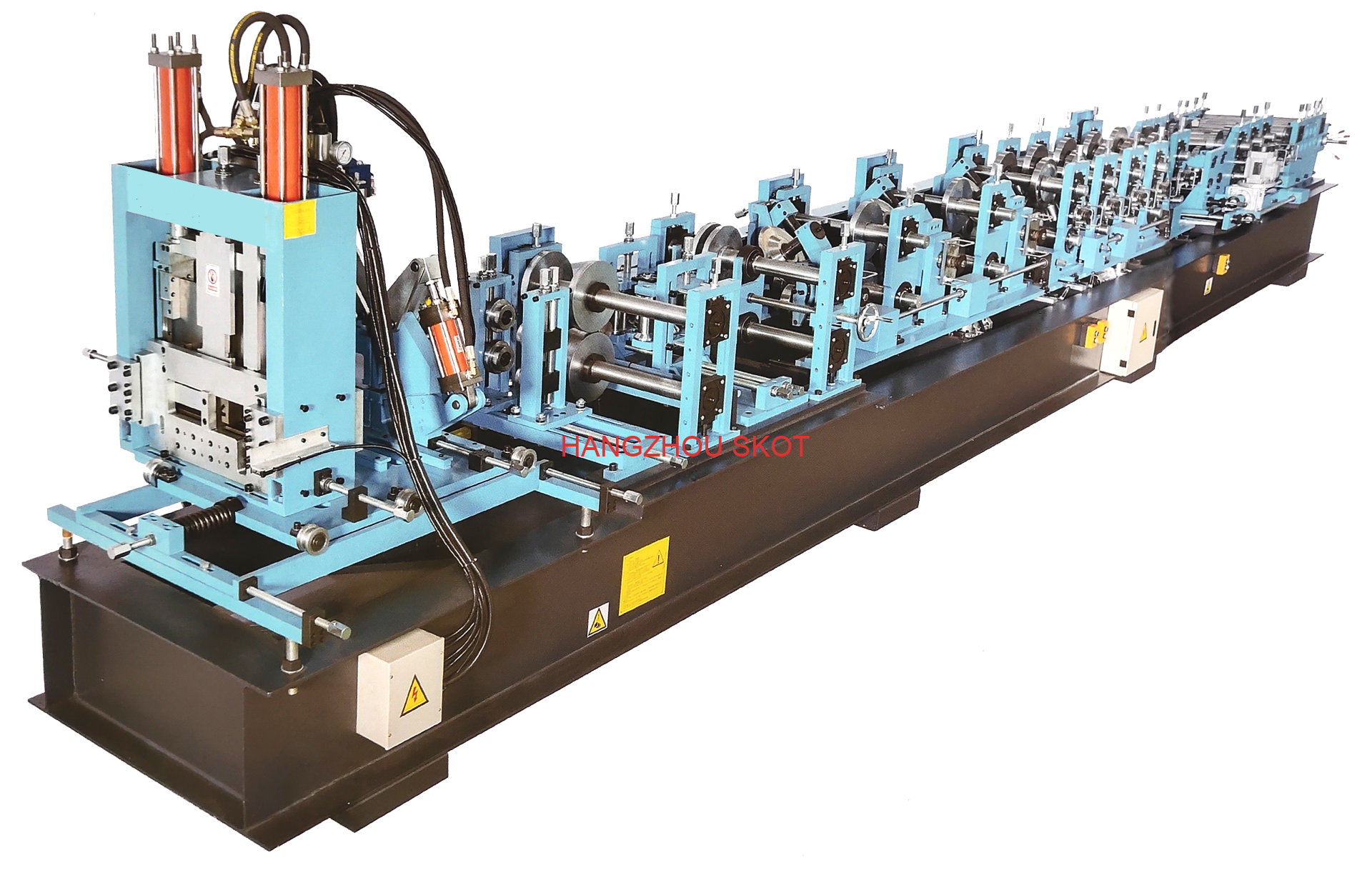

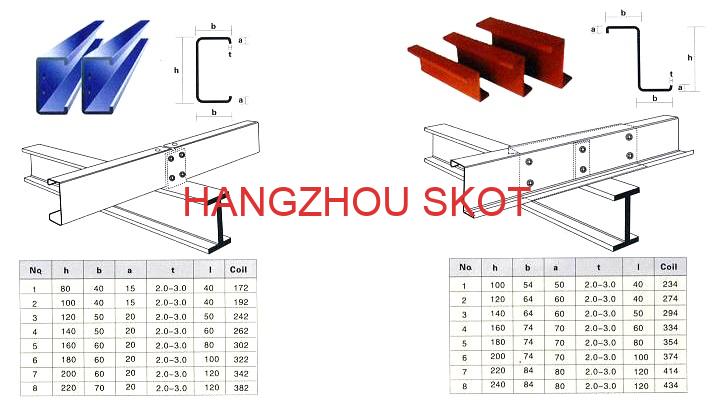

This Roll forming machine for channel (purlin) is manufactured based on the top technology and experiences, and Roll forming machine for channel (purlin) has high durability and convenient management. It exquisitely designs diverse wave forms to meet customers’ requirement, and produces continuously and conveniently world’s top purlin products of C. Z., Omega (Rack), Sigma shape as well as guardrails for road.

* Main Technical Parameters

| Material type | steel strip |

| Material thickness (mm) | 1.5~3.0 |

| Material yield stress (Mpa) | 230~300 |

| Max. forming speed (m/min) | 10~16 |

| Roll material | Bearing steel |

| Roller driven type | Chain transmission |

| Controller & operation | PLC& touch screen and button |

| Hydraulic system pressure (Mpa) | 20 |

| Hydraulic station motor power (kw) | 5.5 |

| Main motor power (kw) | 18.5~22 |

| Total power (kw) | 24~27.5 |

| Total weight (ton) | 12 |

* Process Sketch

Uncoiling the sheet ⇨ Sheet guiding ⇨ Straightening ⇨ Pre-punching ⇨ Roll forming ⇨ Rectifying ⇨ Post-cutting ⇨ Panels to the supporter.